Way back to the year 2020 when a global pandemic hit the whole world, it forced everyone around the globe to make drastic changes to their lifestyle for survival. People could never have gotten more cautious with social distancing and various quarantine norms being followed; Evidently, not helping to curb the virus! People had to resort to wearing a face mask and shields, gloves, and other protective gear. Although the face masks partially ensured that the deadly virus would not pass through masks and created an initial line of defense against the virus, let us not forget that they also blocked a lot of air, making it difficult to breathe. Besides, face masks also get uncomfortable with prolonged usage. The Rebreather mask targets this discomfort and ensures higher safety against the virus or any other contaminants.

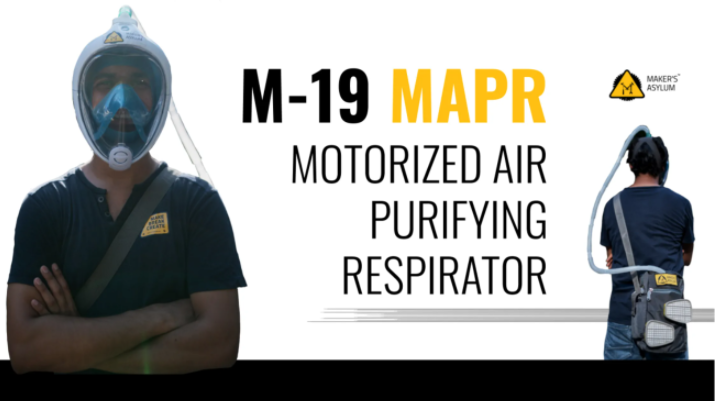

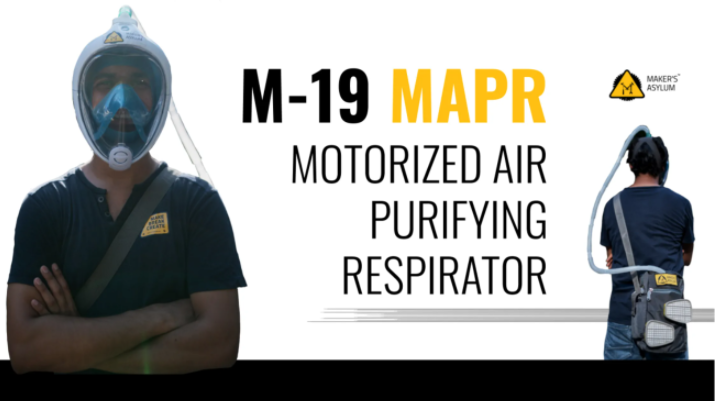

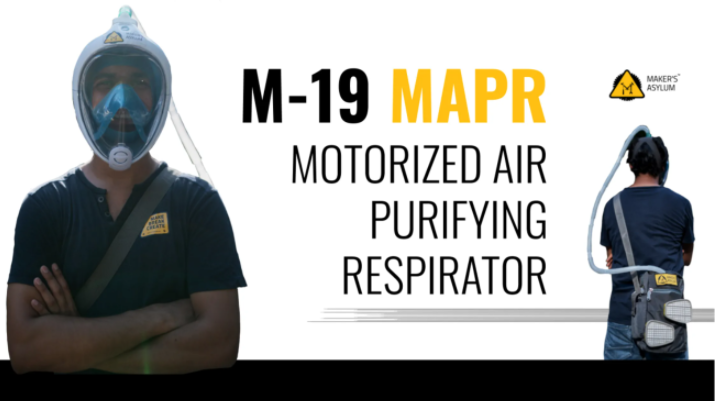

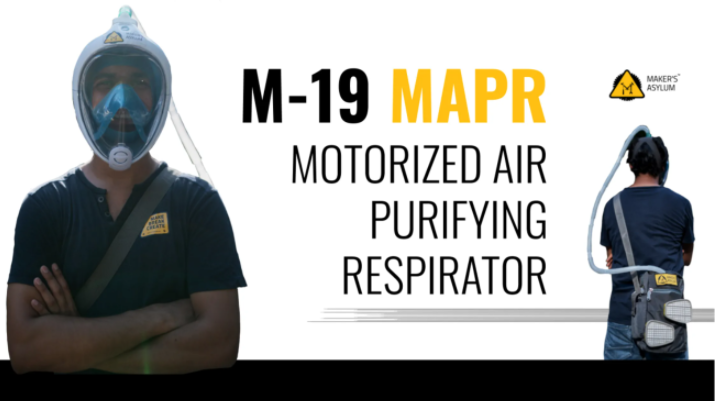

Initial Idea:

The idea started with the Motorised Air Purifying Respirator or M-19 MAPR, as we call it here at the Asylum. We specifically built the device to support the frontline warriors during the pandemic.

We reduced the size of the product to make it more accessible and comfortable for everyday use as the initial product was bulky in size.

Therefore, The solution included reducing the size of the motorized respirator, which included the HEPA filter, and combining the respirator block with a regular face mask instead of a face shield or a helmet.

Electronics:

Our first priority was to figure out the electronics and then focus on the design.

The primary component was the 12V Turbofan, which would push the air from the surroundings into the inlet of the face mask of the user. Then connected the fan to a rechargeable battery, which could supply current at around 8.4 V (connecting two batteries in series).

We introduced a step-up converter (Buck Converter) to regulate the voltage between the power source and the motor; this would convert the input voltage of 8.4 V derived from the battery to a higher value of at least 10V to drive the 12V turbo Fan more efficiently

Prototype:

After multiple iterations, we arrived at the design that we called the Rebreather. The project is referred to as a mini-MAPR.

We created The block casing design with the intention for it to be 3D printed.

The design casing had two sections that separated the filter and the electronics within the casing. The whole enclosure had two separate parts, including the case block and a lid.

We created proper slots and placements to attach each electronic component in its place. The design ensured that the electronics connections would not break within the system.

Way back to the year 2020 when a global pandemic hit the whole world, it forced everyone around the globe to make drastic changes to their lifestyle for survival. People could never have gotten more cautious with social distancing and various quarantine norms being followed; Evidently, not helping to curb the virus! People had to resort to wearing a face mask and shields, gloves, and other protective gear. Although the face masks partially ensured that the deadly virus would not pass through masks and created an initial line of defense against the virus, let us not forget that they also blocked a lot of air, making it difficult to breathe. Besides, face masks also get uncomfortable with prolonged usage. The Rebreather mask targets this discomfort and ensures higher safety against the virus or any other contaminants.

Initial Idea:

The idea started with the Motorised Air Purifying Respirator or M-19 MAPR, as we call it here at the Asylum. We specifically built the device to support the frontline warriors during the pandemic.

We reduced the size of the product to make it more accessible and comfortable for everyday use as the initial product was bulky in size.

Therefore, The solution included reducing the size of the motorized respirator, which included the HEPA filter, and combining the respirator block with a regular face mask instead of a face shield or a helmet.

Electronics:

Our first priority was to figure out the electronics and then focus on the design.

The primary component was the 12V Turbofan, which would push the air from the surroundings into the inlet of the face mask of the user. Then connected the fan to a rechargeable battery, which could supply current at around 8.4 V (connecting two batteries in series).

Prototype:

After multiple iterations, we arrived at the design that we called the Rebreather. The project is referred to as a mini-MAPR.

We created The block casing design with the intention for it to be 3D printed.

The design casing had two sections that separated the filter and the electronics within the casing. The whole enclosure had two separate parts, including the case block and a lid.

We created proper slots and placements to attach each electronic component in its place. The design ensured that the electronics connections would not break within the system.